Navigating the complexities of a cruise ship’s cross-connection control program can be a daunting task for Public Health Officers (PHOs), especially those new to the industry. Even with an Environmental Health degree, many PHOs may find themselves unprepared for the technical intricacies of potable water systems and backflow prevention, as these topics are often not comprehensively covered in their formal education.

However, stepping outside your comfort zone is essential for PHOs. Embracing unfamiliar challenges with courage and determination is key. While additional specialist training would be beneficial, it may not always be accessible or financially viable. Nevertheless, this should not discourage you from addressing this crucial water safety topic. By facing these situations directly, you will enhance your confidence and broaden your skill set.

This two-part article aims to equip PHOs with a comprehensive understanding of cross-connection control and backflow prevention. In this first part, we will break down the basics, offering a beginner-friendly perspective on these critical topics. The second part will delve deeper into mechanical backflow preventers, showcasing real-life examples from on board and providing guidance on selecting the most suitable devices for specific connections.

Table of Contents

What is a Cross-Connection?

A cross-connection is a critical point in a ship’s potable water system where it connects to a source that could introduce contaminants or pollutants. This can happen when unwanted substances—such as wastewater, chemicals, pathogenic microorganisms, or gases—enter the distribution piping, compromising the safety of the intended water supply. Essentially, a cross-connection is a point in the vessel’s fresh water system where the potability of the water can no longer be guaranteed unless corrective action is taken.

Cruise ships rely on a clean water supply for many essential functions, including drinking, cooking, laundry, cleaning, recreational activities (like swimming pools), and basic hygiene such as handwashing and bathing. Ensuring this water remains safe for human consumption is crucial for the health of everyone on board.

Many cross-connections exist at the point of use, such as a faucet where water is dispensed. Technically speaking, once water exits the distribution piping, it can no longer be considered potable as it has been exposed to the environment where contamination is possible. For instance, if you pour yourself a glass of water and only drink half, you shouldn’t pour the remaining water back into the fresh water storage tanks. This doesn’t mean the water in the glass is unsafe to drink, only that it should not be reintroduced into the vessel’s potable water distribution system.

Cross-connections can be either actual or potential:

- Actual Cross-Connection: A permanent link to a source of contamination. For example, a pipe connecting the system to a detergent dispenser in the galley. If there is a drop in water pressure within the potable water system (perhaps due to a pump failure or a sudden high demand), the detergent could be siphoned back into the clean water supply. This backflow can introduce harmful chemicals into the potable water system, making it unsafe for consumption.

- Potential Cross-Connection: A situation where a link could be made, but isn’t currently in place. For instance, an outdoor faucet that might be used to attach a hose for cleaning the deck at night. If the hose is left submerged in a bucket of dirty water and there is a sudden drop in water pressure, that water could be siphoned back into the potable water system. Although the cross-connection isn’t permanent, the risk of contamination exists whenever the hose is connected to the faucet.

Common Examples on a Cruise Ship

Cruise ships, with their complex water system infrastructure, can have hundreds to thousands of cross-connections, depending on their size. Here are some common examples:

- Toilets and Urinals

- Shower Hoses, Spray-Rinse Hoses, and Hose-Bib Connections (a faucet that a hose can be connected to)

- Detergent & Chemical Dispensers

- Laundry Machines

- Recreational Water Facilities like swimming pools and whirlpool spas

- Food Service Equipment such as coffee machines, ice machines, juice dispensers, and combination ovens

- Warewashing Machines

- Boiler and Heating Systems

- Air-Conditioning Units

- Reverse Osmosis Units & Evaporators

- Hospital Equipment (various laboratory devices that use water for cooling or cleaning purposes need backflow preventers)

While it would be ideal to eliminate all cross-connections, they are an unavoidable element of a vessel’s potable water system. Water needs to be utilized throughout the ship, and modifying the distribution piping to eliminate cross-connections isn’t feasible for appliances that require potable water. Therefore, it is crucial to protect these connections with appropriate backflow prevention methods to prevent contamination and ensure water safety.

Cross-Connection Control Programs

Backflow can occur when there is a change in water pressure, causing non-potable substances to flow back into the drinking water supply. To prevent such incidents, a cross-connection control program is an essential part of a vessel’s Water Safety Plan. These programs encompass a range of activities designed to identify, evaluate, and manage or eliminate cross-connections:

- Installing New Backflow Preventers: Implementing devices to isolate and protect cross-connections.

- Regular inspections: Conducting thorough inspections of the water system to check the condition of backflow prevention devices and identify any new or previously overlooked cross-connections.

- Testing Backflow Prevention Devices: Regularly testing devices to ensure they are functioning correctly.

- Implementing Corrective Measures: Taking necessary actions to comply with cruise industry standards.

- Routine Maintenance: Performing ongoing maintenance of plumbing systems to prevent any potential backflow issues.

Although cross-connection control and backflow prevention are closely linked and frequently used in conjunction, they have distinct roles in ensuring water safety. Cross-connection control focuses on identifying and eliminating possible cross-connections, while backflow prevention addresses the methods and devices used to prevent water from flowing backward into the system and potentially causing contamination.

What is Backflow?

In the context of cross-connections, contamination of a ship’s potable water system can occur if three conditions are present:

- A Cross-Connection

- A Source of Contamination

- A Backflow Event

Backflow is the undesirable reversal of water flow—or mixtures of water and other substances—into the distribution pipes of a ship’s potable water system. Typically, water is pumped from the potable water storage tanks located in the engine compartments and flows in one direction to where it is needed: “upward” through the ship via supply pipes, and then back “down” to the engine compartments via return pipes.

While marking the intended direction of water flow on the outside of pipes is good practice, water won’t always follow the arrows; it will seek the route of least resistance. Water naturally moves from areas of high pressure to areas of low pressure, looking for the easiest path. This behavior is governed by the fundamental principles of physics. If the flow direction reverses, it can draw contaminants or pollutants into the drinking water supply through inadequately protected cross-connections.

How Does Backflow Occur?

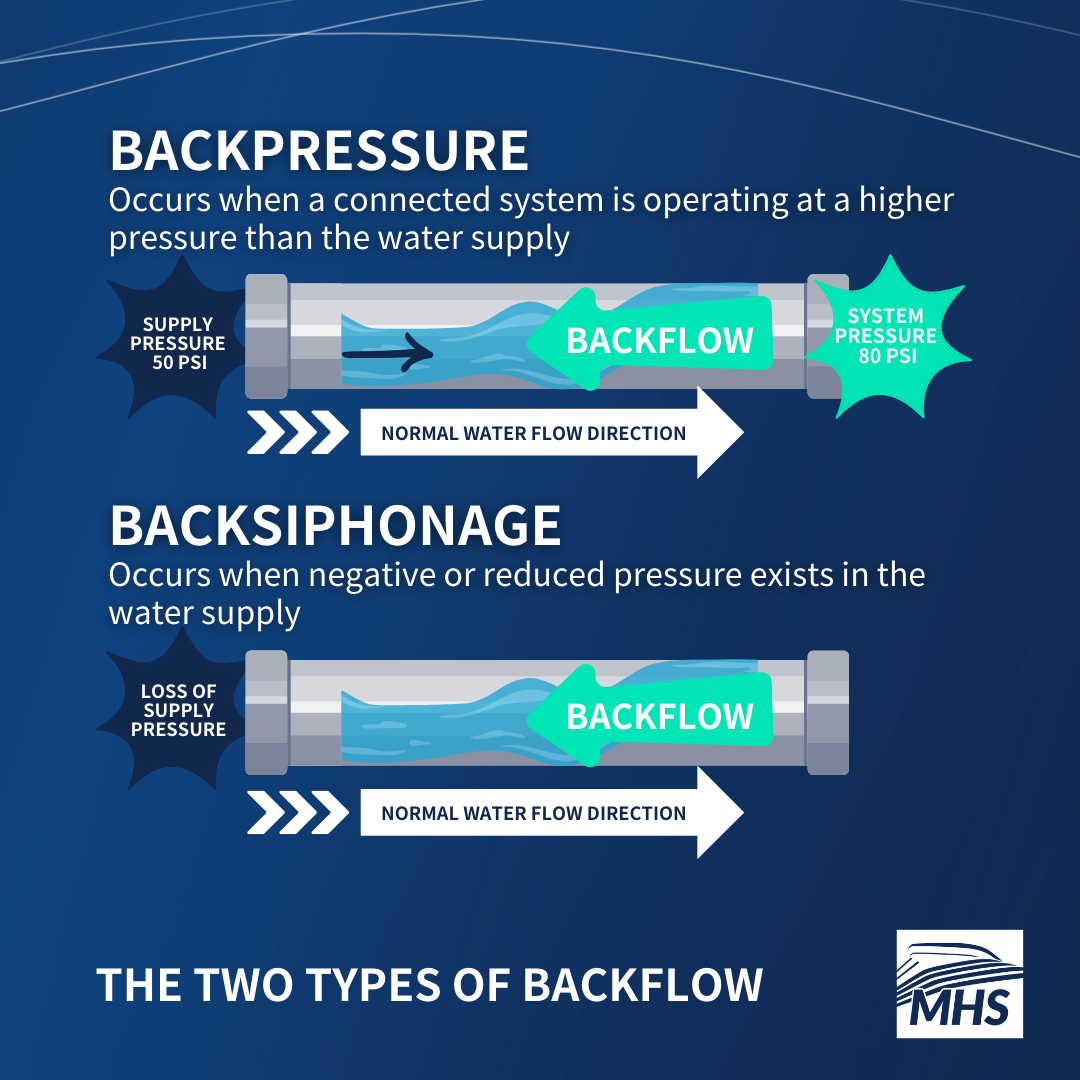

Backflow can occur in two main ways:

Backpressure

- This happens when the pressure in a non-potable system becomes higher than the pressure in the potable water supply. This can force contaminated water to flow backward into the drinking water system.

- Consider a ship’s boiler system where water is heated to generate steam. Boilers can cause backpressure due to a phenomenon known as thermal expansion. When water is heated, its particles gain energy and move more vigorously, causing them to occupy more space. If the pressure in a boiler becomes too high, it can push the boiler water, which may contain chemical additives, back into the potable water supply.

Backsiphonage

- If backpressure is a push from a non-potable appliance connected to the vessel’s potable water system, backsiphonage can be thought of as a pull from the supply side. This occurs when the pressure in the potable water system drops below that of a non-potable source, creating a partial vacuum. This vacuum can pull contaminants or pollutants into the drinking water system.

- This effect is similar to using a straw: when you suck on the straw, the reduced pressure inside your mouth allows atmospheric pressure to push the liquid up the straw. If there’s a sudden drop in water pressure, such as when a main water line breaks, it can create a vacuum that pulls contaminated water from a non-potable source into the drinking water system.

Types of Cross-Connections

Cross-connections can be categorized based on the type of backflow they are subject to:

Direct Connection

Description: A direct connection is where both backpressure and backsiphonage can occur. For backpressure to be possible, there must be a physical connection to a non-potable system that operates at a higher pressure than the potable supply, such as a booster pump, boiler, or fire sprinkler system.

Example: Picture a reserve osmosis (RO) unit that converts seawater into potable water. Seawater is pushed through a semi-permeable membrane under high pressure, allowing water molecules to pass through while blocking most salts and impurities. The RO unit is connected to both the potable water system and a non-potable brine discharge system, which contains water with a high concentration of salt. Normally, the potable water system operates at a lower pressure than the brine discharge system because high pressure is needed to overcome osmotic pressure and force seawater through the membrane, leaving behind concentrated brine. If there is no backflow prevention device, the higher pressure in the brine discharge system can push the non-potable brine back into the potable water supply.

Indirect Connection

Description: An indirect connection is where only backsiphonage can occur. Backsiphonage can be caused by several factors, including a break in a main water line or large demands on a distribution system (such as in the morning when everyone on board is taking a shower), which lowers the supply pressure. Even draining a water system, like a whirlpool spa, can trigger a backsiphonage event.

Example: An example of an indirect connection could be a showerhead submerged in used bath water. If the water pressure drops suddenly, the dirty bath water can be sucked back into the clean water supply through the shower hose.

Selecting the Appropriate Backflow Prevention Method

Water is one of the few resources on board that transcends the customary maritime hierarchies. Whether you’re a passenger in a premium suite or a contractor in the crew accommodation area, the water you use is the same. Therefore, safeguarding the safety of potable water is particularly important, as contamination can potentially affect every soul on board.

Choosing the right backflow protection for each cross-connection is a critical part of this process. Not all backflow prevention devices are created equal; the type needed depends on various factors, including installation cost, complexity, and the specific requirements of the water system and the connected appliance.

Ensuring robust cross-connection control on a cruise ship starts with a comprehensive survey of the vessel’s potable water system. While these surveys are time-consuming and require meticulous attention to detail, they are essential for long-term safety and compliance. Relying on inspections to identify missing devices is risky and inefficient. As a Public Health Officer, collaborating with the vessel’s engineers is crucial. Their in-depth understanding of the water system’s complexities is invaluable for pinpointing all cross-connections and implementing the necessary backflow protection measures. This survey involves examining every part of the vessel’s potable water system, from the main supply piping to each fixture, appliance, and connection.

When selecting the most suitable backflow prevention solution, it’s important to consider the costs, potential pressure loss, and ongoing maintenance requirements. Why install a complex, testable backflow prevention assembly if a simple, non-testable device can adequately protect the water supply? It is also important to note that installing a backflow preventer can alter the hydraulic dynamics of a water system—the way water flows and behaves in a plumbing system.

Backflow preventers can cause a reduction in water pressure or volume, which can affect the performance of fixtures and appliances, especially those that require a strong flow of water to function properly. To mitigate this issue, it’s important to choose the right type and size of backflow preventer and to ensure it is properly installed and maintained. Regular maintenance can help minimize any potential pressure loss.

Remember, each installation is unique, and there is no one-size-fits-all solution for preventing backflow. Just because a certain backflow prevention device was used for a similar cross-connection elsewhere on the ship doesn’t mean it will be suitable for a different connection. It’s essential to evaluate each cross-connection individually to determine the most effective and efficient backflow prevention method.

Understanding the Degree of Hazard

The primary consideration when choosing backflow protection is the actual or potential danger posed by a cross-connection, known as the “Degree of Hazard.”

Potable water, as defined by the Vessel Sanitation Program, is water that is safe for drinking, washing, bathing, and other uses. It must be free from impurities that could cause disease or harmful effects and must conform to World Health Organization (WHO) drinking water standards.

The degree of hazard helps determine whether a cross-connection poses a low risk (non-health hazard), affecting only the water’s taste or appearance, or a high risk (health hazard), potentially causing illness or death. Understanding the difference between pollutants and contaminants is crucial for assessing these risks:

- Pollutants: Substances that may affect the color, taste, or odor of potable water but do not pose a direct health threat. They are considered a lesser hazard.

- Contaminants: Substances that can directly threaten human health. These can be chemicals, fluids containing pathogens, or any other harmful substances. Contaminants pose the highest degree of hazard to the potable water system.

Choosing the Right Backflow Preventer

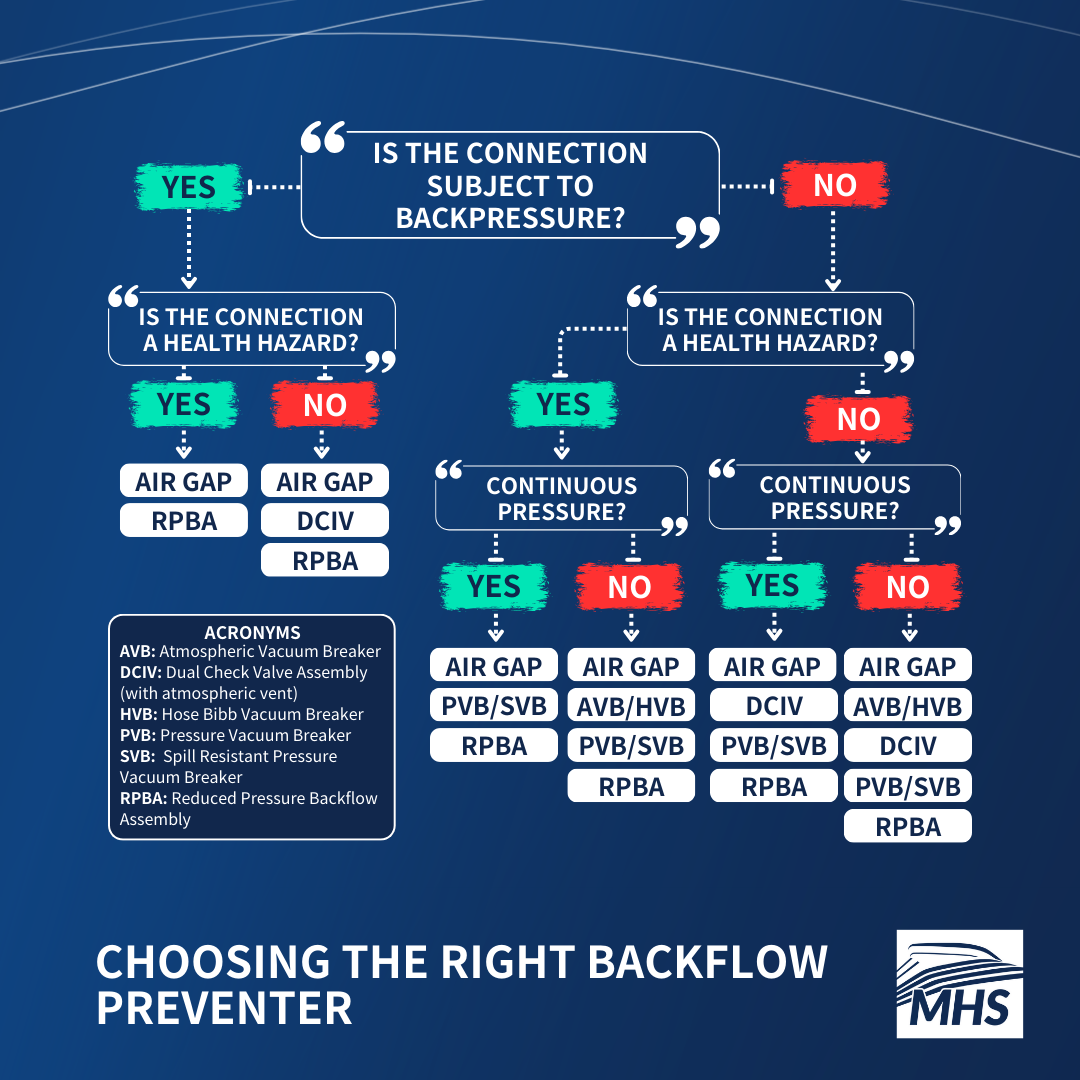

When it comes to selecting the right backflow prevention device, there are four key questions to guide your decision:

- Type of Connection: Is the connection subject to both backsiphonage and backpressure (direct connection) or only backsiphonage (indirect connection)?

- Health Hazard: Is the connection a health hazard or a non-health hazard?

- Pressure Requirements: Will the application require continuous pressure, or will it only be pressurized on a limited basis (i.e. non-continuous pressure)? Continuous pressure is defined as more than twelve hours of pressure in any 24-hour period. For example, a boiler feed line is always under pressure, while the potable water supply to a vacuum toilet system is only pressurized when in use (e.g., when you flush the toilet).

- Regulatory Compliance: Does the device chosen comply with cruise industry standards? The VSP 2018 Operations Manual outlines specific requirements for cross-connections and the necessary backflow prevention methods. For instance, water softener and mineralizer drain lines must be equipped with either an air gap or a reduced pressure backflow assembly.

Non-Mechanical Option: The Air Gap

An air gap is one of the most effective backflow prevention methods available because it creates a physical separation between the potable water supply and any potential contaminants. Here’s why it’s so effective and how it works:

- How It Works: An air gap is a vertical space between the water outlet and the flood level of a fixture. This gap prevents contaminated water from flowing back into the clean water supply. To be effective, an air gap must be at least twice the diameter of the supply pipe and always a minimum of 25 millimeters (1 inch).

- Applications: Air gaps are widely used in many plumbing fixtures and appliances. On a cruise ship, a common application is the space between the faucet (tap) and the flood level of a sink basin.

- Effectiveness: An air gap can protect against both health hazards and non-health hazards, as well as backsiphonage and backpressure.

However, air gaps have limitations. Installing an air gap eliminates all system pressure, and once water passes through an air gap, it may no longer be considered potable. Therefore, it is not suitable for all scenarios. For example, in a boiler feed line, maintaining consistent pressure is crucial for the efficient operation of the heating system. An air gap would disrupt this pressure, making it unsuitable for such applications.

In situations where an air gap isn’t feasible, mechanical devices and assemblies come into play. In the second part of this article, we’ll explore various mechanical backflow preventers, their specific uses, and why they are essential for certain applications on a cruise ship.